Kooperacja

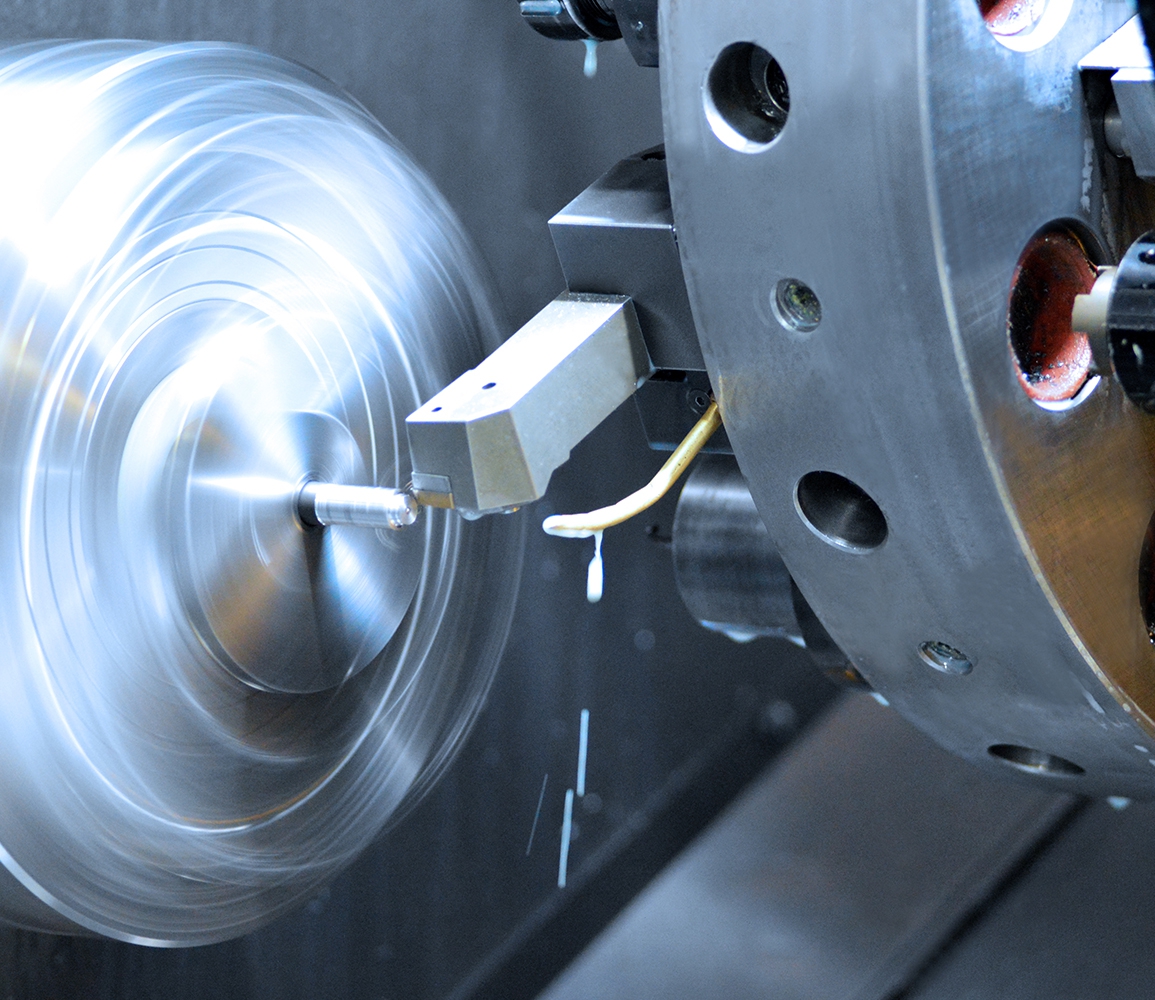

Chętnie podejmujemy się podwykonawstwa w oparciu o procesy produkcyjne

Usługi

Oferujemy obróbkę metali, doradztwo techniczne oraz nakładanie powłok lakierniczych i PVD

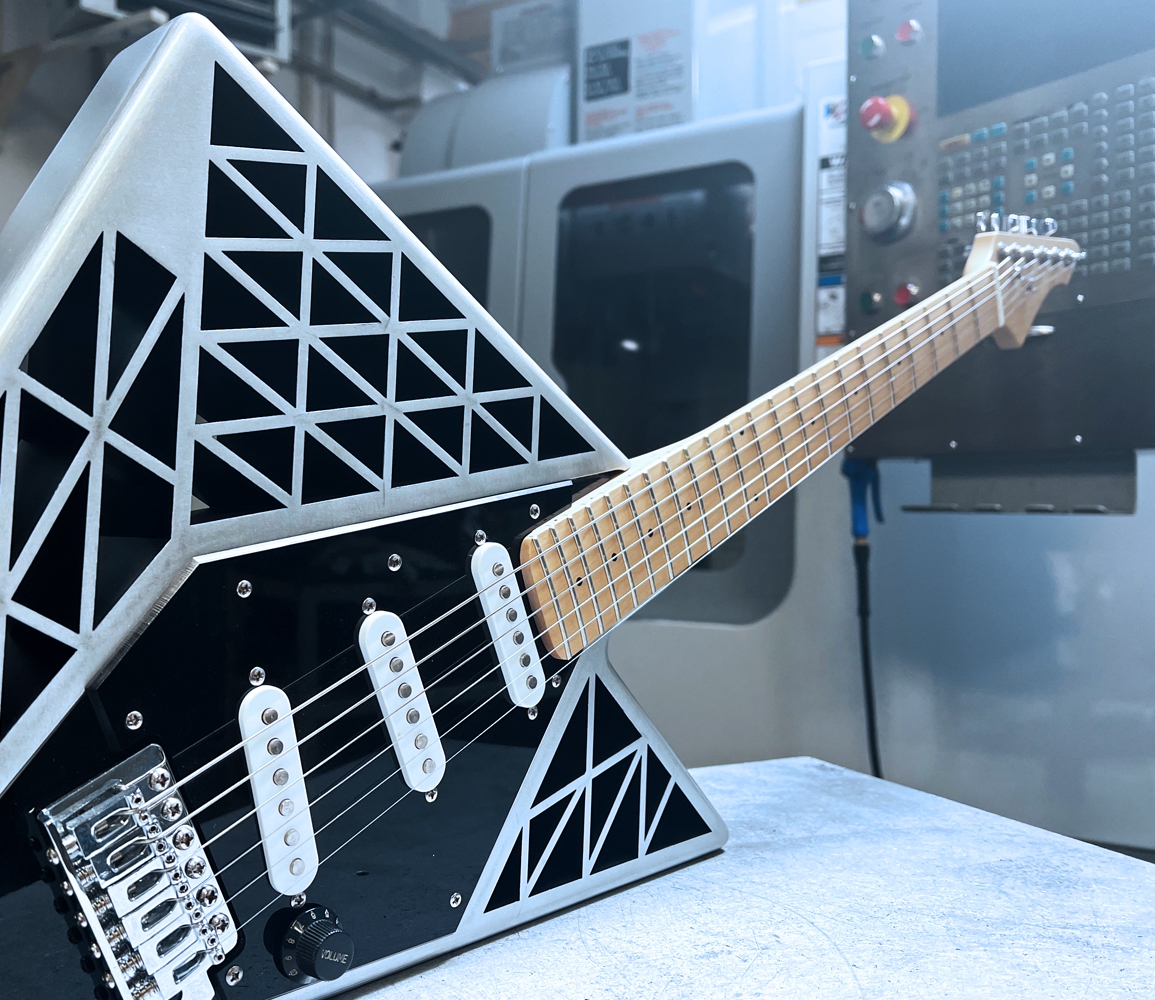

Produkcja

Zajmujemy się

odlewnictwem metali i tworzyw sztucznych, tłoczeniem taśm, formowaniem drutu

odlewnictwem metali i tworzyw sztucznych, tłoczeniem taśm, formowaniem drutu

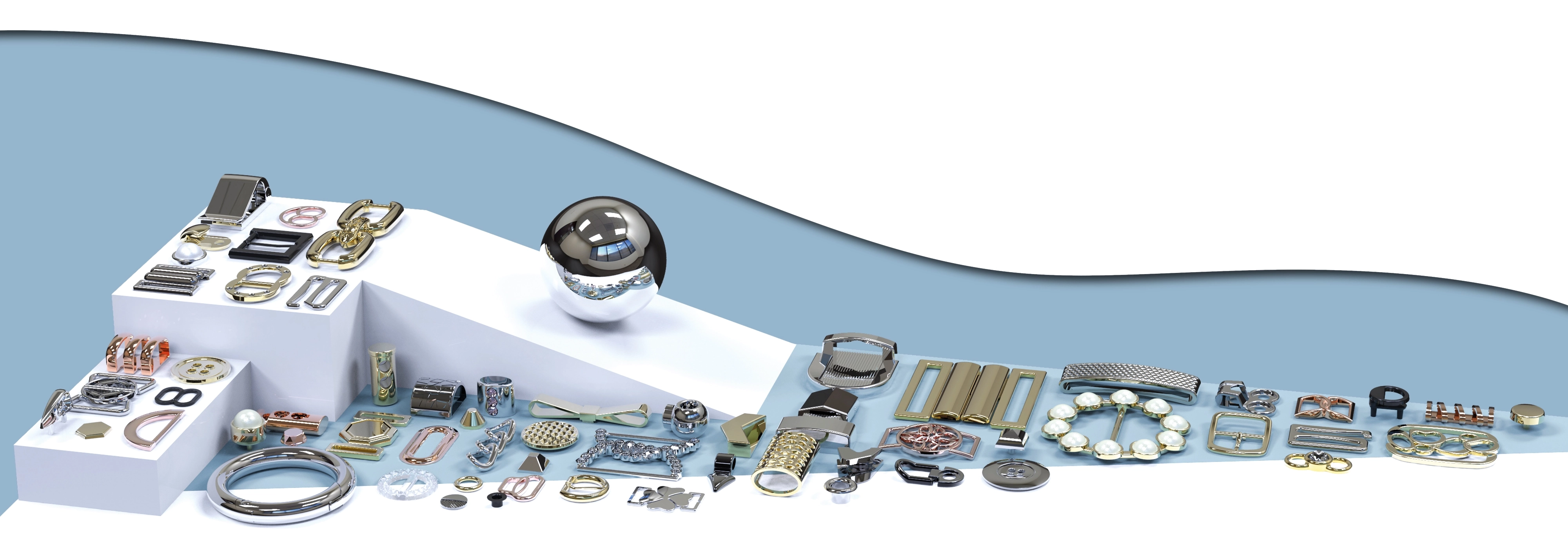

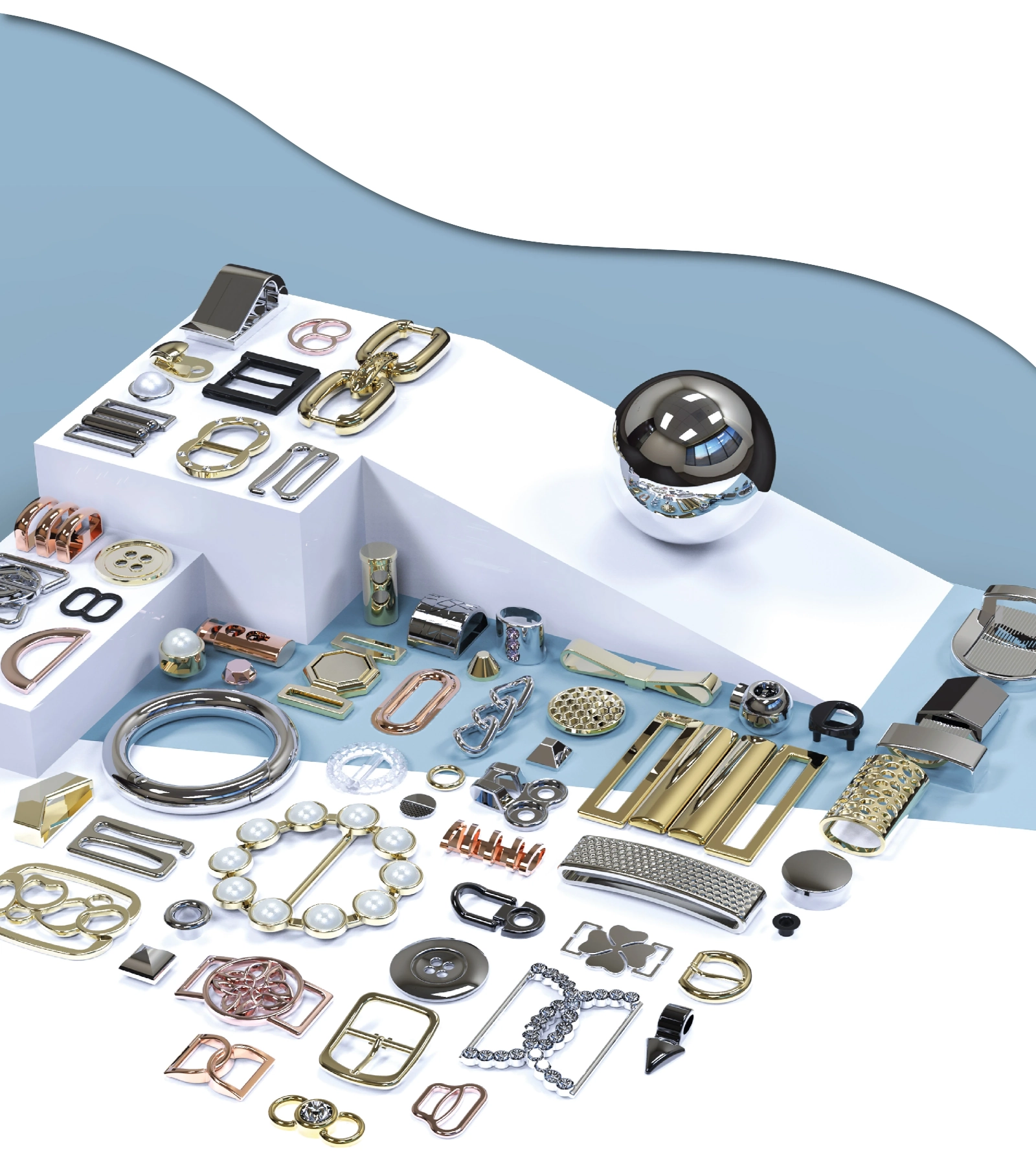

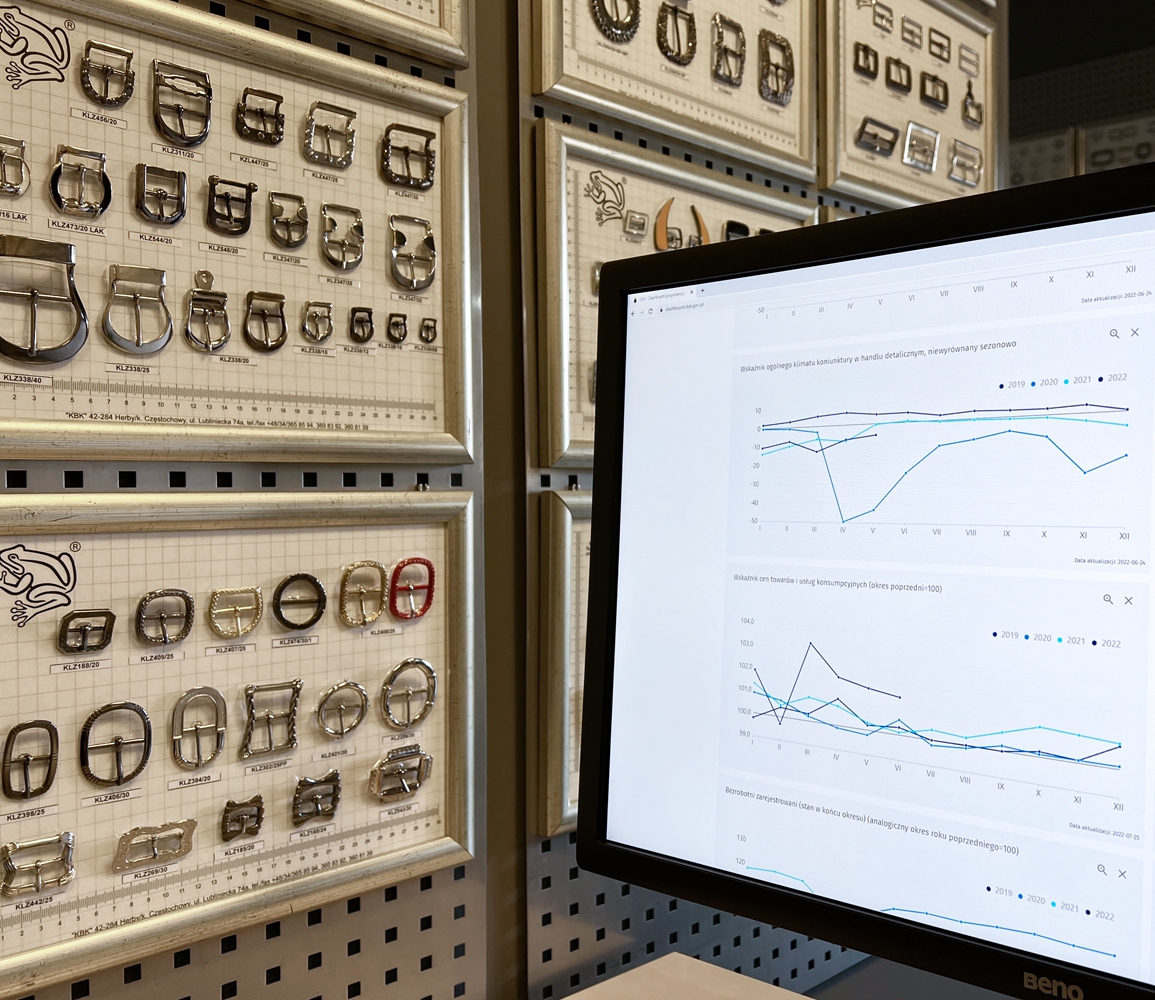

Sprzedaż produktów

Dysponujemy szeroką ofertą ozdób i dodatków m.in. do odzieży, obuwia i wyrobów kaletniczych.